Micropiles shorings

Home > Ground shoring > Micropiles shorings

What is the ground shoring system and what is it for. Particularities in micropile diaphragm walls

A ground shoring is a temporary metal structure that replaces a future slab while excavation is in progress, absorbing the soil pressure behind the diaphragm walls.

The goal is that the diaphragm walls (designed to eventually work under bending moments and shear forces between slabs) have support points in the excavation stages leaving bending lengths similar to those that the diaphragm walls will have once the execution of the basement is finished and the slabs can bear loads.

As a rule of thumb, if a thorough analysis of the diaphragm walls is to be avoided, each future slab should be replaced by an equivalent level of shoring as close as possible to the slab itself.

The number of strut levels can be optimized (i. e. reduced) by re-analysing the diaphragm walls and checking that stresses, displacements and crack width are under control during all excavation stages.

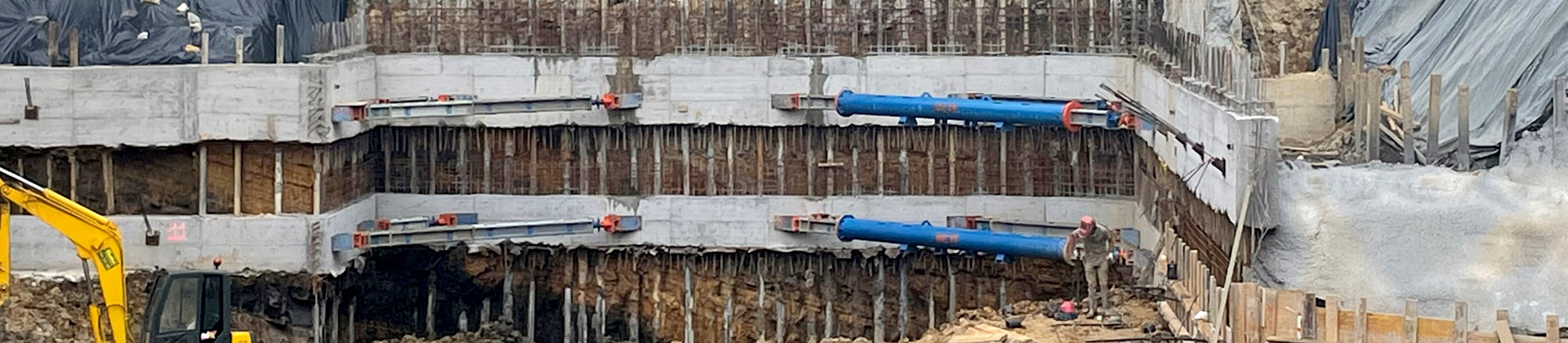

In the case of micropile diaphragm walls the struts do not reach the diaphragm wall directly. A waler beam is arranged around the pile wall such that each strut takes the thrust coming from multiple micropiles.

Another advantage of the waler beam is that it can absorb the irregularities of the micropile wall, more visible than in the case of a continuous diaphragm wall.

The strut system for micropile walls is practically identical to that used for concrete piles walls, with the difference that since the micropiles are made of steel and not concrete, it is necessary to weld a plate to certain micropiles, in order to bolt brackets that will support the self weight of the waler beams and struts.

Once all the waler beams have been placed, the struts are pinned to the anchor plates which have been previously bolted to the waler beams.

Ours being a 100% modular and bolted system, all gaps are eliminated and the exact strut length is attained by tightening the jack that each strut carries.

Main ground shoring systems

INCYE’s ground shoring systems are based on three types of equipment: meccano formed by Megaprop beams and accessories, Granshor modular trusses system and Pipeshor tubular prop system.